Korean memory factory SK Hynix announced that it has completed and started to supply the first high-K EMC material high-efficiency heat-dissipating mobile DRAM product to use in the industry. SK Hynix pointed out that EMC (eccentric oxygen die seali...

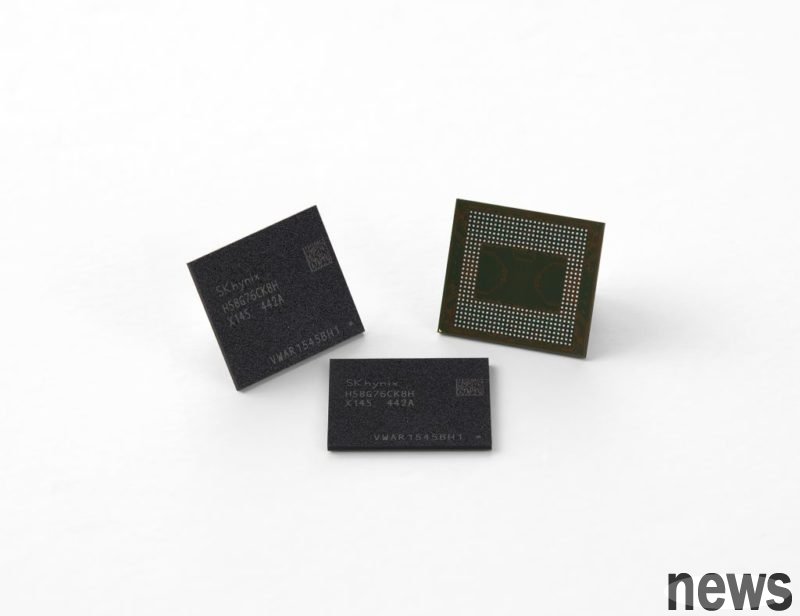

Korean memory factory SK Hynix announced that it has completed and started to supply the first high-K EMC material high-efficiency heat-dissipating mobile DRAM product to use in the industry.

SK Hynix pointed out that EMC (eccentric oxygen die sealing) is a necessary material in the semiconductor rear-process used to seal and protect semiconductors from external environments such as moisture, heat, shock and static electricity, and to exert heat dissipation channels. High-K EMC refers to the use of materials with higher thermal conductivity (K value) in EMC, thereby improving thermal conductivity.

SK Hynix said that as the hot-explosion problems caused by high-speed data processing during edge AI operation become increasingly serious, it has become the main reason for the performance of smart phones. Therefore, the product effectively solves the hot problems of high-performance flagship mobile phones and has won high praise from customers around the world.

SK Hynix emphasizes that the latest flagship mobile phones currently use PoP (Package on Package) structure, that is, vertically stacking DRAM on the mobile processor. Although the structure can efficiently utilize limited space and improve data processing speed, it also causes the heat generated by the mobile processor to gather inside the DRAM, which in turn affects the performance of the adjuster.

To solve this problem, SK Hynix is committed to improving the thermal conductivity of DRAM packaging key material EMC. The company mixed aluminum oxide (Alumina) on the silicon dioxide (Silica) base used in traditional EMC to develop new High-K EMC materials. The heat conductivity of the new material is increased to 3.5 times compared with traditional materials, thereby reducing the heat resistance of the heat vertical transmission pathway by 47%.

In addition, the improvement of heat dissipation performance helps improve the overall performance of smart phones, while reducing power consumption can extend battery life and increase product life. The company expects that this product can attract high attention and strong demand from the equipment industry. SK Hynix PKG Product Development As Vice President Lee Kyu-jen said that this product not only improves performance, but also effectively solves the difficulties of high-performance smart phone users, which has a profound and significant meaning. SK Hynix will continue to base its material technology innovation and firmly establish its technological leadership position in the new generation of mobile DRAM market.